24 November 2025

It was supposed to be perfect…

A pristine white column rising above Manhattan — 1,400 feet of geometric precision piercing the skyline. When 432 Park Avenue opened in 2015, it was marketed as a triumph of modern design. The penthouses sold for tens of millions of dollars. Celebrities and investors rushed in. The tower became an icon of what human engineering could achieve. And then, the cracks appeared…

By 2025, inspectors and engineers were reporting hundreds of fissures along its concrete facade. Pieces of spalled concrete had to be removed from some of the highest floors. Water seeped through the ceilings. Elevators failed. Residents complained of creaking and swaying. And as lawsuits began flying between developers, engineers, and condo boards, one number kept surfacing:

$160 million. The estimated cost to repair the building’s exterior, according to engineering reports reviewed by The New York Times. How did one of the world’s most luxurious towers end up in this position? The inspections happened; the insight didn’t.

The damage didn’t start with the concrete system. It started with the data they never collected.

The Real Risk: What You Can’t See, You Can’t Defend

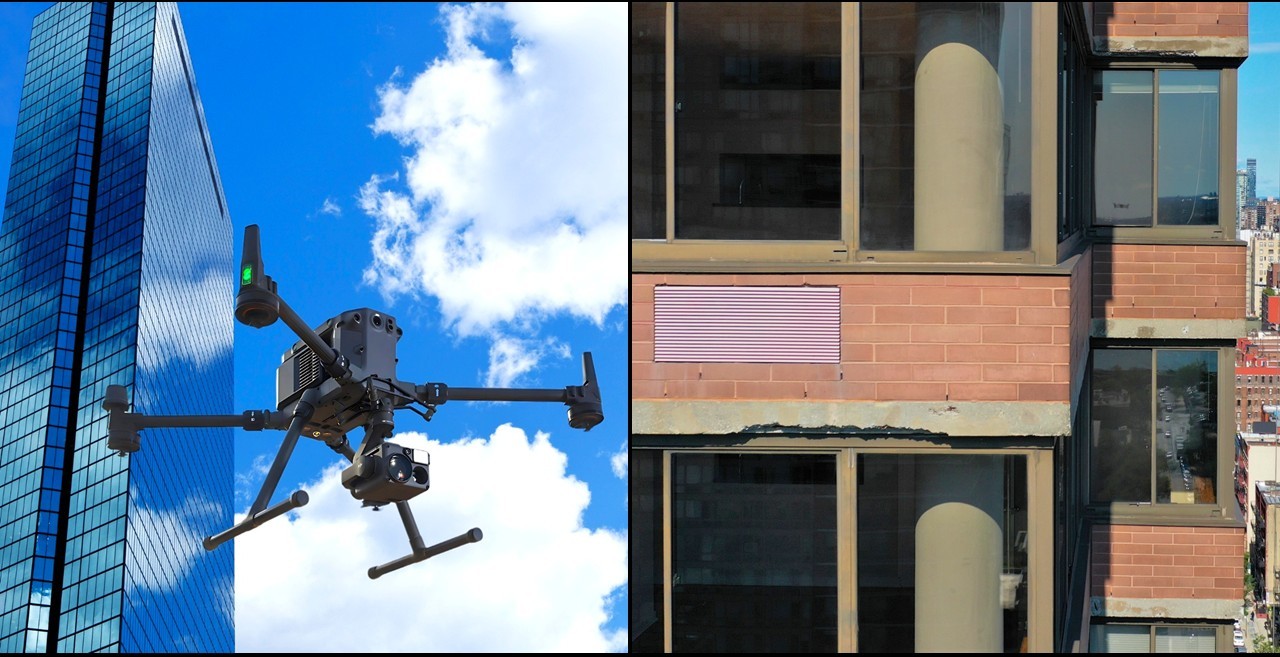

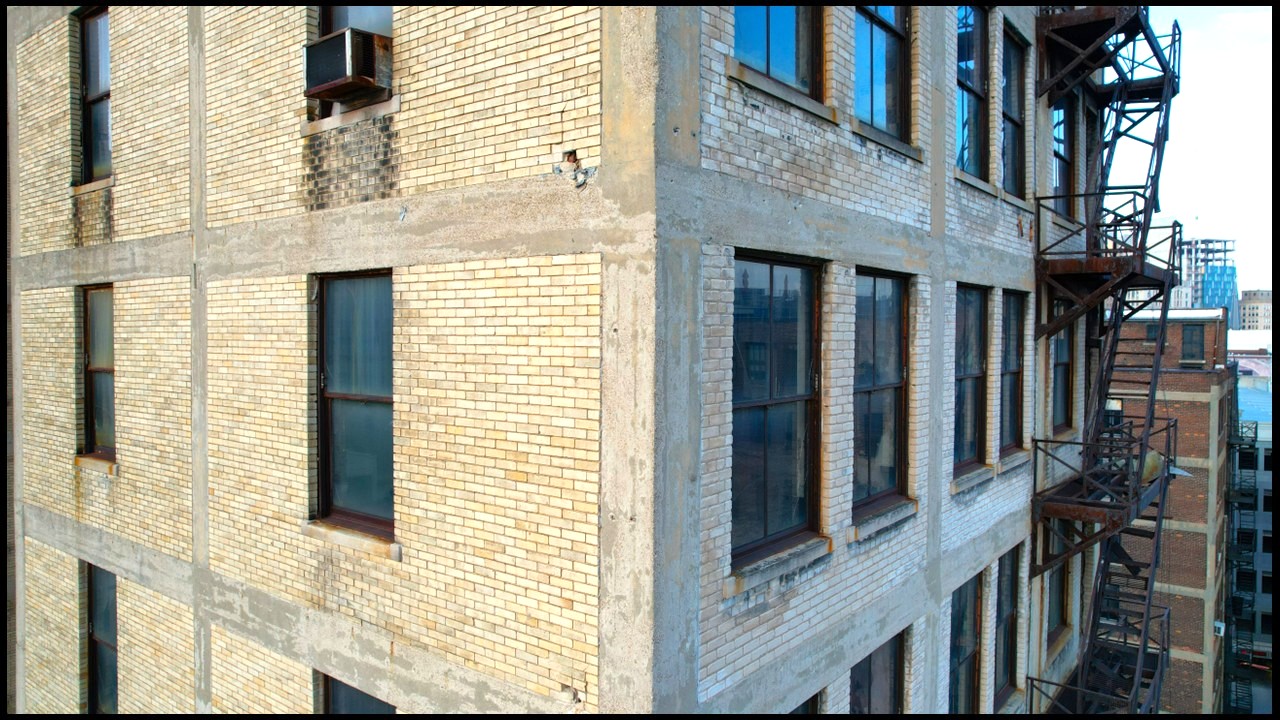

In cities like New York, facade inspection laws require buildings over six stories to undergo visual examinations every five years. It’s a sensible standard…in theory. But as materials, designs, and environmental stressors have evolved, that five-year gap has become a chasm.

Concrete expands and contracts in response to temperature shifts. Sealants fatigue under UV exposure. Micro-cracks invite moisture, which corrodes rebar and accelerates deterioration from the inside out. All of this can happen in a single winter, let alone five years. So, when a failure finally becomes visible, the physical damage is only part of the problem.

The bigger crisis is informational: no one can say with certainty when the issue began, how quickly it developed, or who should have caught it. That absence of proof — not the crack itself — is often what leads to litigation.

Drone-based facade documentation changes that equation entirely. It closes the visibility gap before lawyers ever enter the room.

From Compliance to Continuity

Traditional facade inspections are snapshots; brief moments in time that satisfy regulatory requirements but do little to reveal change. Drone inspections, on the other hand, create continuity: a living record of the facade’s condition that evolves with the building itself.

Working personally in this space as a DSP, I’ve seen how this shift in approach transforms not only maintenance, but risk management. Every image becomes evidence. Every flight becomes a timestamp. Every data set builds a history that’s impossible to dispute.

That continuous record does three things exceptionally well: it documents, it detects, and it defends.

Document: Establish a Baseline Before Problems Begin

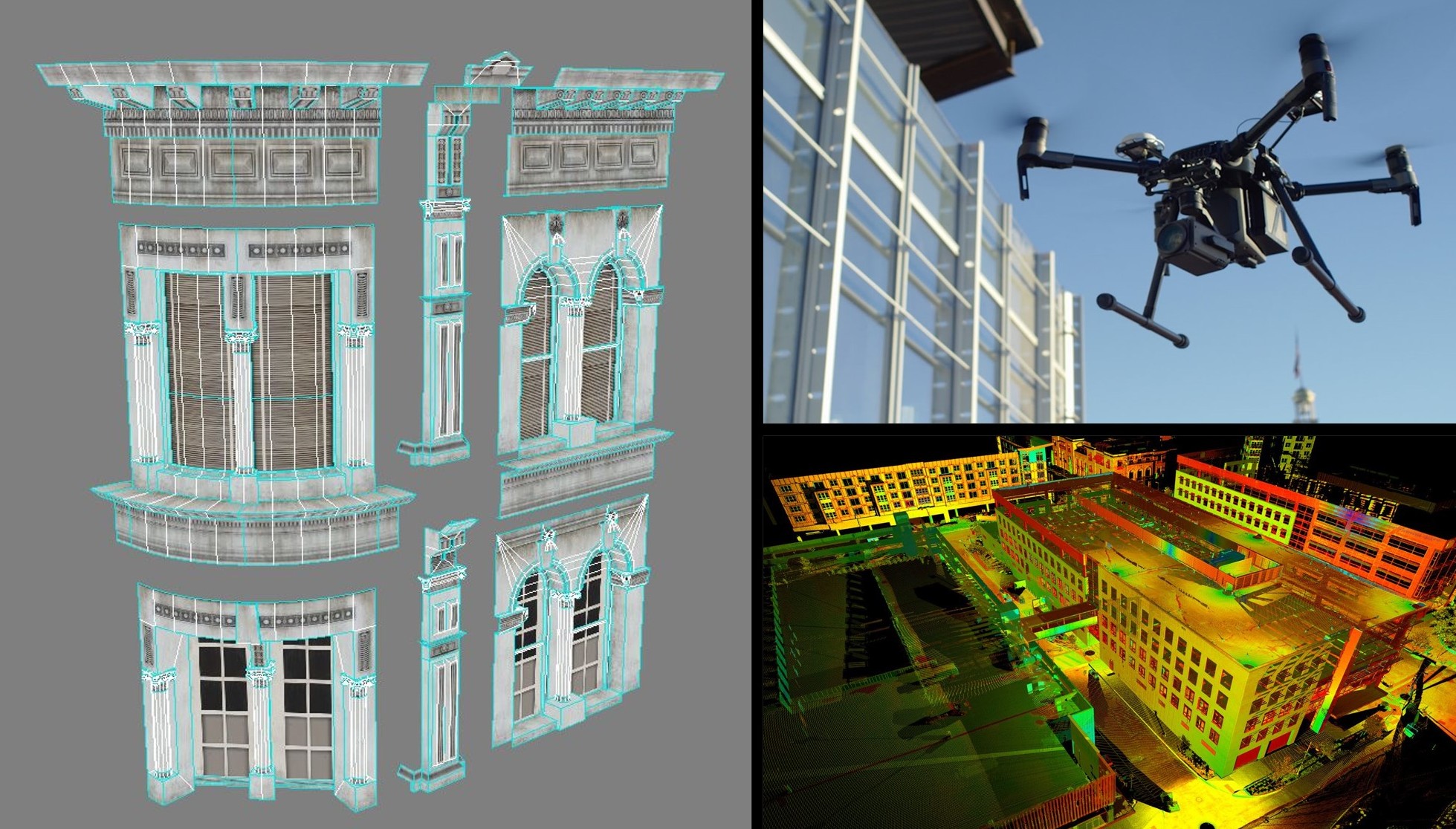

The first flight after construction or acquisition is the most valuable one, you’ll ever run. We capture a full visual baseline—high-resolution, geotagged imagery of every panel, joint, and sealant line. Each photo is indexed and archived, creating a verifiable record of “day one” condition.

Why It Matters: When a hairline crack shows up three years later, you no longer have to rely on memory, paperwork, or opposing testimony. You have proof. You can demonstrate when the issue emerged, how it progressed, and whether your team responded appropriately.

In litigation, that’s the difference between assumption and evidence.

Detect: Monitor Change Before It Becomes a Crisis

Inspection shouldn’t be a reaction to damage; it should be a preventive mechanism. By flying facades on a regular schedule (annually, semi-annually, or after major weather events), drone photogrammetry creates pixel-level comparisons over time. AI-driven analytics then flag minute deviations, cracks, discoloration, or sealant shrinkage that human eyes might miss. The advantage is not only speed, but foresight. When change is quantified, you can prioritize repairs based on measurable progress rather than gut instinct. That means fewer emergency projects, lower repair costs, and far less exposure to negligence claims.

As the 432 Park Avenue case shows, degradation rarely happens overnight. What appears to be a sudden failure is often years in the making—years that could have been documented and addressed had the right tools been available.

Defend: Turn Visual Data into Legal Protection

If a facade defect ever leads to litigation, the question isn’t just whether the damage occurred, it’s whether the responsible party acted reasonably to prevent it. That’s where drone data becomes invaluable. Each inspection produces high-resolution imagery tied to GPS coordinates, flight paths, and metadata. The result is a chain of evidence that’s difficult to dispute and easy to authenticate.

When owners, engineers, and contractors have a shared, time-stamped record, the blame game collapses. Instead of speculation, there’s documentation. Instead of accusation, there’s accountability.

And when the case never makes it to court at all, it’s because everyone can clearly see what happened and when, that’s the most powerful protection of all.

The Data That Ends Disputes

What Drone Facade Inspections Deliver:

● Proactive Documentation: Baseline imaging of every facade surface, down to millimeter-scale detail.

● Time-Stamped Change Tracking: Photogrammetry and AI analytics identify degradation long before it’s visible to the naked eye.

● Defensible Evidence: Metadata-backed imagery withstands legal scrutiny, demonstrating due diligence and timely maintenance.

● Reduced Liability: Transparent data sharing keeps developers, engineers, and ownership aligned — minimizing disputes and insurance risk.

● Lower Lifetime Costs: Early detection converts nine-figure renovations into routine upkeep.

Case in Point: Lessons from Billionaires’ Row

The story of 432 Park isn’t just about cracks in concrete; it’s about the fractures that form when information is missing.

Had routine drone-based facade monitoring been implemented from the start, the building’s owners and engineers would have had a decade-long timeline of imagery showing where and when the facade began to deteriorate. That evidence could have supported timely repairs, prevented water infiltration, and provided defensible proof of diligence.

Predictive Maintenance: The Smart Path Forward

We often remind clients that facades don’t fail overnight. They fail quietly, incrementally, and predictably, even when you think you’re watching closely enough. Establishing a consistent cadence of drone-based facade inspections enables maintenance to shift from reactive to proactive. High-resolution, geospatial aerial data provides engineers with real-time visibility into surface deterioration, material fatigue, and structural anomalies, creating early warnings that safeguard public safety and prevent costly emergency repairs.

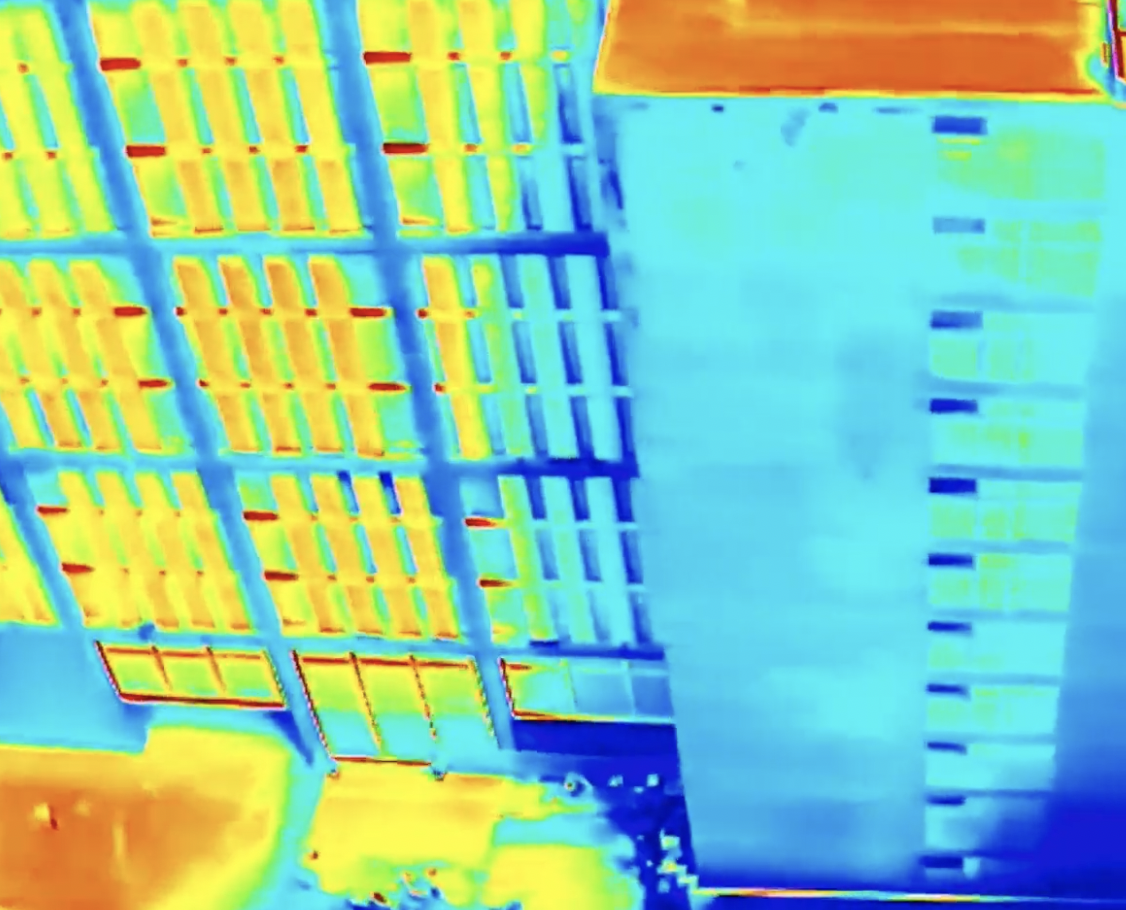

The advantage lies in precision and efficiency. Drones equipped with interchangeable payloads RGB, thermal, lidar, and ultra-high-definition video can capture a comprehensive dataset in minutes without ever touching the facade. This speed matters, especially in dense urban environments like New York, Boston, Chicago, San Francisco, Los Angeles, Dallas, and Miami, where scaffolding logistics and lane closures can significantly slow traditional inspection methods for weeks.

Drone-based facade inspections are no longer just an emerging technology. They’re the new standard for intelligent, compliant, and cost-effective asset management, protecting buildings, budgets, and reputations from the ground up. Because in the end, it’s not just about preventing cracks in concrete.

It’s about preventing cracks in confidence, accountability, and trust.

Get a Closer Look!