14 April 2023

The rapid advancement of 3D printing technology has led to a paradigm shift in various industries, including the ever-evolving world of drone manufacturing.

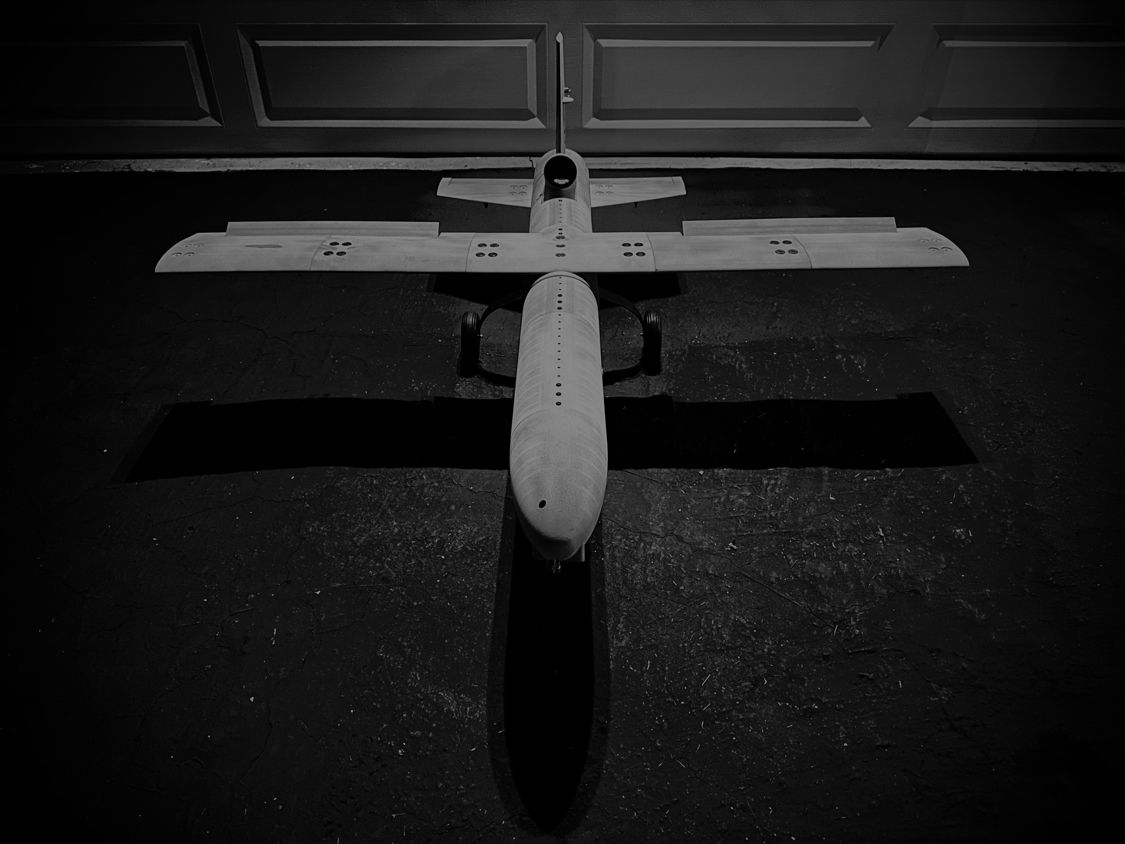

Firestorm, a trailblazing company that specializes in producing 3D-printed Unmanned Aerial Systems (UAS) vehicles has embraced the benefits of additive manufacturing and iterative design to develop state-of-the-art aerial systems. With its origins in the context of the Ukraine war combined with Firestorm's unique manufacturing approach, the advantages of using 3D printing technology, the company's rapid development of the Block 10 UAS Firestorm has only just scratched the surface of its mission to democratize the air.

One of the most significant advantages of 3D printing technology is its ability to facilitate rapid prototyping and iterative design. Firestorm leverages this technology to continuously refine and optimize its UAS drone designs. By experimenting with different configurations and materials, the company can develop highly efficient and cost-effective drones. Additive manufacturing enables Firestorm to produce intricate geometric shapes and structures that would be challenging, if not impossible, to create using conventional methods. Consequently, the company can develop lightweight, aerodynamically efficient drones that improve flight performance and energy consumption.

Moreover, 3D printing offers the flexibility to customize drones according to specific mission requirements, ensuring that each drone is optimally designed for its intended purpose. This adaptability is crucial for addressing the varying needs of clients, especially in the context of military applications where the ability to tailor drones to specific mission parameters is of paramount importance.

Firestorm's use of 3D printing technology enables a remarkably fast production process. The company can manufacture an entire drone within a day, with the airframe taking only nine hours to print. This accelerated production timeline is a game-changer in the drone manufacturing industry, allowing Firestorm to quickly respond to market demands and customer needs.3D printing significantly reduces production costs by eliminating the need for expensive tooling and molds typically associated with traditional manufacturing methods. Consequently, Firestorm can allocate its resources to research, development, and product enhancement, giving the company a competitive edge in the market. This cost reduction also makes the company's products more accessible to clients with limited budgets, which is particularly relevant in the context of military and government contracts.

Watch!

Alpha Flight from Firestorm Labs on Vimeo.

Firestorm's innovative manufacturing approach is exemplified by the rapid development of the Block 10 UAS, which progressed from concept to preliminary design to first flight in under three months. The Block 10 UAS is now being scaled up to increase its range and payload capacity to over 300 miles and 10 pounds, respectively. This impressive accomplishment demonstrates Firestorm's commitment to innovation and continuous improvement, enabled by the efficient use of 3D printing technology.

The rapid development of the Block 10 UAS also highlights the company's ability to stay ahead of the competition by quickly conceptualizing new vehicles. In an industry where the pace of innovation is accelerating, the ability to rapidly develop and deploy new technologies is crucial for maintaining a competitive advantage. By leveraging 3D printing technology, Firestorm has positioned itself as a leader in the drone manufacturing industry.

The genesis of Firestorm can be traced back to the Ukraine war when the company recognized the need for cost-effective, efficient tools to empower warfighters. Firestorm's commitment to developing affordable, high-performance UAS drones is particularly relevant in military contexts, where limited budgets and the need for rapid deployment are critical factors. By harnessing the advantages of 3D printing technology, Firestorm can manufacture drones at a fraction of the cost of traditional methods. This affordability, combined with the company's focus on constant iteration, enables Firestorm to quickly adapt its designs to the evolving needs of warfighters, maintaining a technological edge on the battlefield.

The success of Firestorm and its 3D-printed UAS drones serves as a powerful example of the potential for additive manufacturing to revolutionize the drone industry. As 3D printing technology continues to advance, we will likely see further innovations in drone design and production, with an increasing emphasis on customization, efficiency, and sustainability.

For Firestorm, the future looks promising, as the company continues to refine its manufacturing processes and expand its product offerings. By staying at the forefront of 3D printing technology and maintaining its commitment to constant iteration, Firestorm is well-positioned to capitalize on the growing demand for advanced UAS drones, both in military and civilian applications.

In addition to military applications, Firestorm's advanced drones have the potential to revolutionize various civilian sectors, such as agriculture, infrastructure inspection, and disaster response. As the demand for versatile and efficient aerial systems grows, Firestorm's innovative approach to drone manufacturing will continue to shape the future of the industry.

As 3D printing technology advances and becomes more accessible, we will likely witness further breakthroughs in drone design, manufacturing, and customization.

As Firestorm continues to push the boundaries of what is possible with 3D-printed UAS drones, the company is well-positioned to take advantage of emerging market opportunities. The combination of rapid production, cost-effectiveness, and customized solutions make Firestorm’s drones appealing to a wide range of potential customers, both in the military and civilian sectors.

In the military domain, Firestorm’s drones can serve a variety of purposes, including reconnaissance, surveillance, search and rescue, and much more. By offering drones that can be tailored to the specific needs of each mission, Firestorm can provide military forces with the flexibility and adaptability they require to address ever-changing operational environments.

In the civilian sector, there is enormous potential for the application of Firestorm’s drones in areas such as agriculture, infrastructure inspection, and disaster response. For example, 3D-printed drones can be used to monitor crop health, optimize irrigation, and detect pests or diseases in agriculture, leading to improved yields and reduced resource consumption. In the infrastructure sector, drones can be used to inspect bridges, powerlines, and other critical structures, enabling early detection of potential issues and reducing the need for costly and time-consuming manual inspections.

Disaster response is another area where Firestorm’s drones could have a significant impact. In the aftermath of natural disasters, drones can be quickly deployed to assess the damage, locate survivors, and deliver essential supplies, improving response times and saving lives. The ability to rapidly manufacture and customize drones to meet the specific requirements of each disaster scenario further enhances their value in this context.

Firestorm’s success in the 3D-printed UAS drone market could also be bolstered through strategic collaborations and partnerships. By working with other companies, research institutions, and government agencies, Firestorm can access new resources, technologies, and markets, further accelerating its growth and expanding its reach. For example, partnerships with software developers could lead to the integration of advanced artificial intelligence capabilities into Firestorm’s drones, enabling greater autonomy and improved performance in challenging environments.

Firestorm has positioned itself as a leader in the world of drone manufacturing by embracing 3D printing technology and iterative design to create advanced UAS drones. The company’s commitment to rapid production, cost-effectiveness, and continuous improvement has set a new standard for the industry and opened up a wide range of potential applications in both the military and civilian sectors.

The origins of Firestorm in the context of the Ukraine war underscore the company’s dedication to empowering warfighters and providing cost-effective solutions that meet the needs of modern military operations. As the drone industry continues to evolve, Firestorm and other innovative companies will play a crucial role in shaping its future, developing advanced aerial systems that have the potential to revolutionize a wide range of applications and industries. Firestorm is well on the way to democratizing the air.