Guest Blog by Avari Aerospace

Power lines are a crucial means for distributing electricity and other forms of energy, but they can also be a safety hazard. Drones offer an innovative way to inspect power lines.

Why Power-Line Inspection is So Important

Power lines are a necessity in modern society. Without them, all of our homes and offices would be without electricity. But considering the high voltage involved, it's important to know when power lines are at risk of failure. Power-line inspections can reveal damage and structural defects that could lead to future problems. When there's a problem with them, getting it fixed quickly is essential. But doing this in some cases requires climbing up high poles or working on towers. This can be dangerous and expensive, because one wrong move could result in serious injury or even death. That's where drones like the Arin SWAP or Echo come in.

How to Use Drones in Power-Line Inspection

Power-line inspection is a process that companies use to inspect power lines for damage and identify when and where repairs need to be made. The equipment that is used for the inspection is typically carried by workers or mounted on trucks. Inspection can also be done from the ground using binoculars or by using a camera mounted on an airplane.

Drones are a great solution for power-line inspection. They can fly up to the lines and provide a 3D map of the infrastructure to look for any defects or damage. This is a much cheaper and faster way of inspecting power lines than using various methods with ground crews. There's also less risk to workers compared to other methods.

Plan the Mission

Power-line inspection is a complicated process and defining the geography of the inspection is essential for a successful mission plan. Inspection coordinates can be uploaded into any flight planning and control software to create the best mission route for the job. The best software options will also geotag and process the images you collect during the mission.

Equip your Drone with the Right Tools

Thermal-imaging cameras are designed to measure the intensity of thermal radiation emitted by an object. This technology is small and drone mountable, so it can be used on power lines that typically have high voltage. It can detect what the human eye cannot see, such as fractures in joints, voids in insulation, and holes in wire coverings. This technology will make it easier to locate defects before they get worse.

Some drones are used with thermal cameras to detect any heat anomalies that might indicate damage or problems in the power lines. Other drones have 3D scanners mounted on them that collect data about the shape of the poles and surrounding areas. The Arin SWAP enables you to mount multiple cameras or sensors to the vehicle and easily swap out tools and equipment to carry out any mission.

Check out the Arin SWAP in Action!

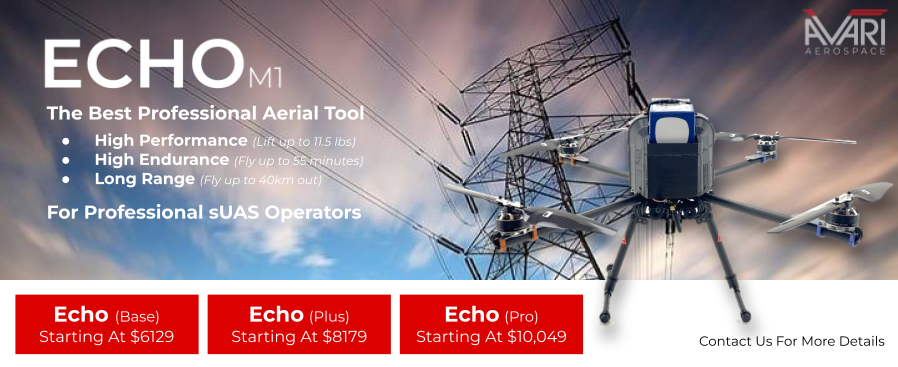

Benefits of using the Echo

Large carbon-fiber drones can be used for power line inspection in places where it would be unsafe for a human to go or where damage to infrastructure creates too much risk for smaller drones. This is a safer option than using helicopters that have the potential for propeller strikes on lines.

The Echo enables you to lift up to 11.5lbs of equipment and tools, exchange equipment and/or tools for different parts of each mission, and fly up to 25 miles of lines.

Conclusion

Power-line inspection is a difficult albeit important job. Twenty-six power-line workers are electrocuted every year. Many companies have switched over to drone inspections of power lines in order to avoid this problem. Drones can fly up close and take photos of power lines, eliminating any risk of electrocution, while providing a safe way to inspect power lines that was previously unavailable, and add the agility and flexibility that traditional air vehicles lack.

It's easy for a malfunctioning power line to do untold damage to people and property, so it's important that it's inspected as often as possible. Drones like the Arin SWAP and Echo make the process safer for workers and more efficient.